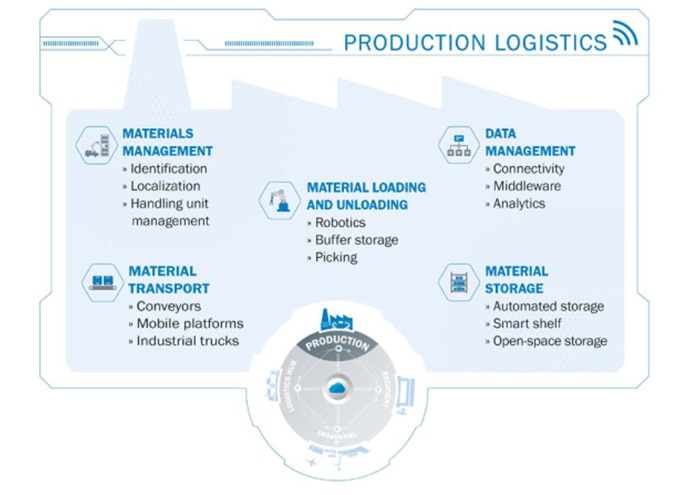

The "Big Picture" illustrates the whole process

To try out: Our virtual warehouse

Click here to go to our virtual warehouse. There you can stop at various stations and learn more about solutions and the use of our sensors.

For review: Our on-demand webinars

For reference: Our whitepapers

Machine Building/Machine Tools

Intelligent production logistics for the consumer goods industry

Modern production logistics: challenges and opportunities for machine building

Increasing efficiency using real-time localization solutions

From silicon to smartphone: Intelligent production logistics for electronics industry