Annual Report 2020

THE SMALLEST PARTICLES – THE GREATESTPRECISION

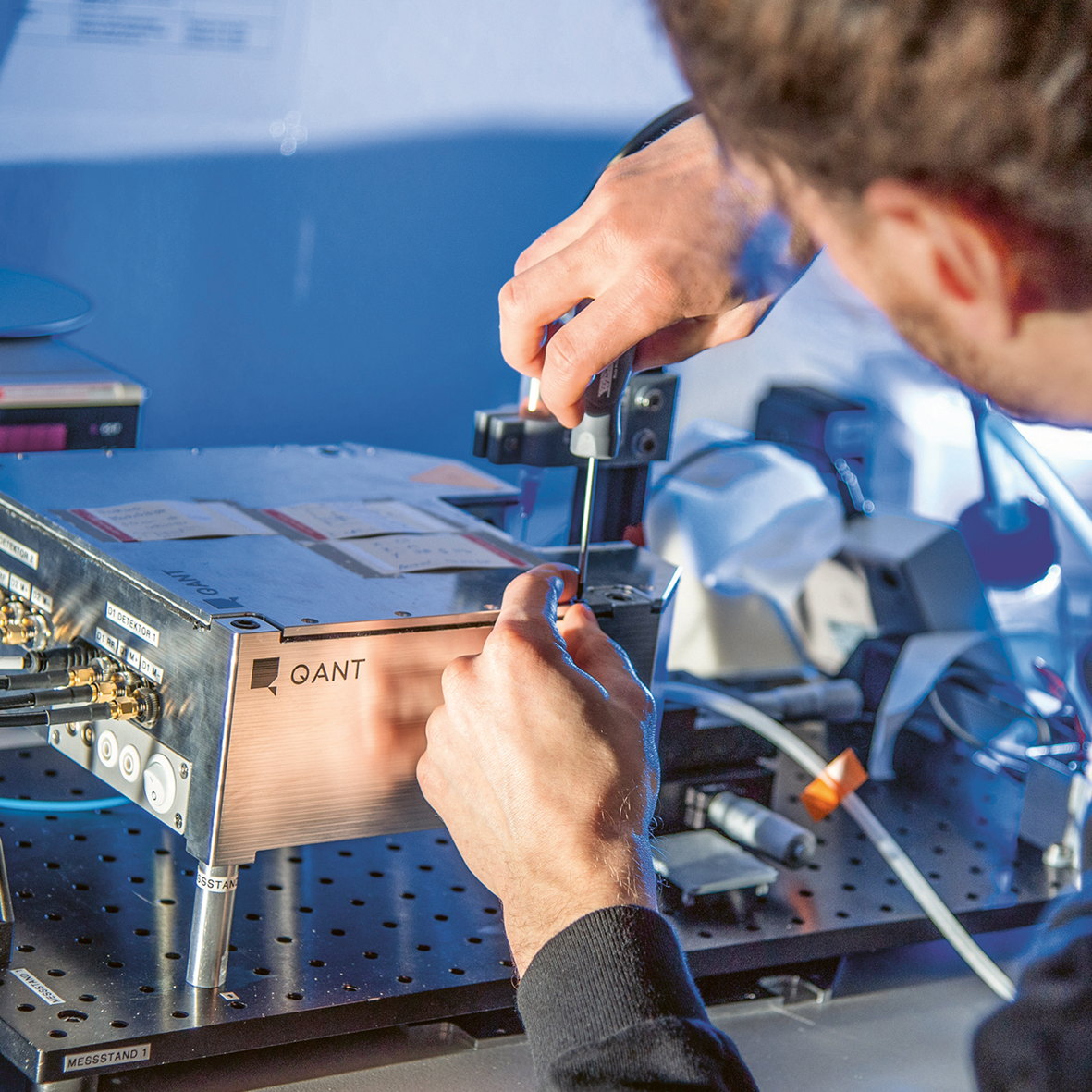

A new dimension in measurement technology: SICK develops the world’s first industrial quantum optical sensor in cooperation with Q.ANT.

Quantum sensors achieve rapid and precise measurements of even the smallest of particles. The measurement devices exploit the effects of quantum physics for particle analysis and detecting particle characteristics, and have so far only been used in scientific settings. A cooperation between SICK and Q.ANT (a wholly-owned subsidiary of TRUMPF) will now, for the first time, enable this technology for industrial environments.

The two high-tech companies have been working together since 2020. SICK is responsible for developing the applications and marketing the product while Q.ANT – as a specialist in quantum technology – will produce the measurement technology, and thus the technological heart of the sensor. “This cooperation is a perfect match,” says Kai Klinder, Head of Program and Engineering, Particle Analyzers, Global Business Center Analyzers. “SICK’s agile way of working and Q.ANT’s start-up culture fit very well together. We are convinced that our joint innovation will, in future, be a key technology for industry.”

Whereby the industrial quantum sensor opens up a new dimension in two ways: With the help of laser light, it registers data about the size, distribution, concentration, speed and direction of movement of the smallest of particles in a detector field. The smallest particles in the measurement area are tinier than a fifth of a micrometer – and are thus two hundred times smaller than the diameter of a human hair.

Using quantum effects the sensor can perceive additional details without interfering signal noise, and hence provide highly precise data in a quality hitherto impossible in industrial environments. In industrial applications this sensor can, for example, provide continuous realtime measurements of particle size distributions in a powder – during the production of medicines, coating powders or cement, say, as well as anywhere where the correct mixture of ingredients is important. Up to now, such measurement processes have taken place in a laboratory away from the production line, delaying processes and potentially leading to errors. Quantum sensors provide such data in real time during production, so this information can immediately be used for further production. This saves time and prevents manufacturing errors. Many other applications are conceivable, for example analyzing sources of particle contamination in the semiconductor industry, or determining the constituents in air.

SICK wants to expand its worldwide innovation and technology leadership in the sector with its entry into the business field of quantum sensors. “We have already successfully completed the function test of the world’s first quantum optical sensor for serial production,” says Kai Klinder. “Now it is important to put this revolutionary technology into practice, and exploit the market opportunities available here.” The first use of the sensor as a ‘concept product’ is planned for 2022.